clamp on ultrasonic flow meter installation guidelines

The difference is the mount. Just select a suitable measuring point input the pipeline parameters at the measuring point into the flowmeter and then fix the sensors on the pipe.

Installing A Clamp On Ultrasonic Flow Meter Industrial Process Control Instrumentation Control Valve Blog

Manufacturers cannot control the quality of a given field installation and must provide latitude.

. Clamp on ultrasonic flow meter installation guidelines. Locate an optimal position where the straight pipe length is sufficient. It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications.

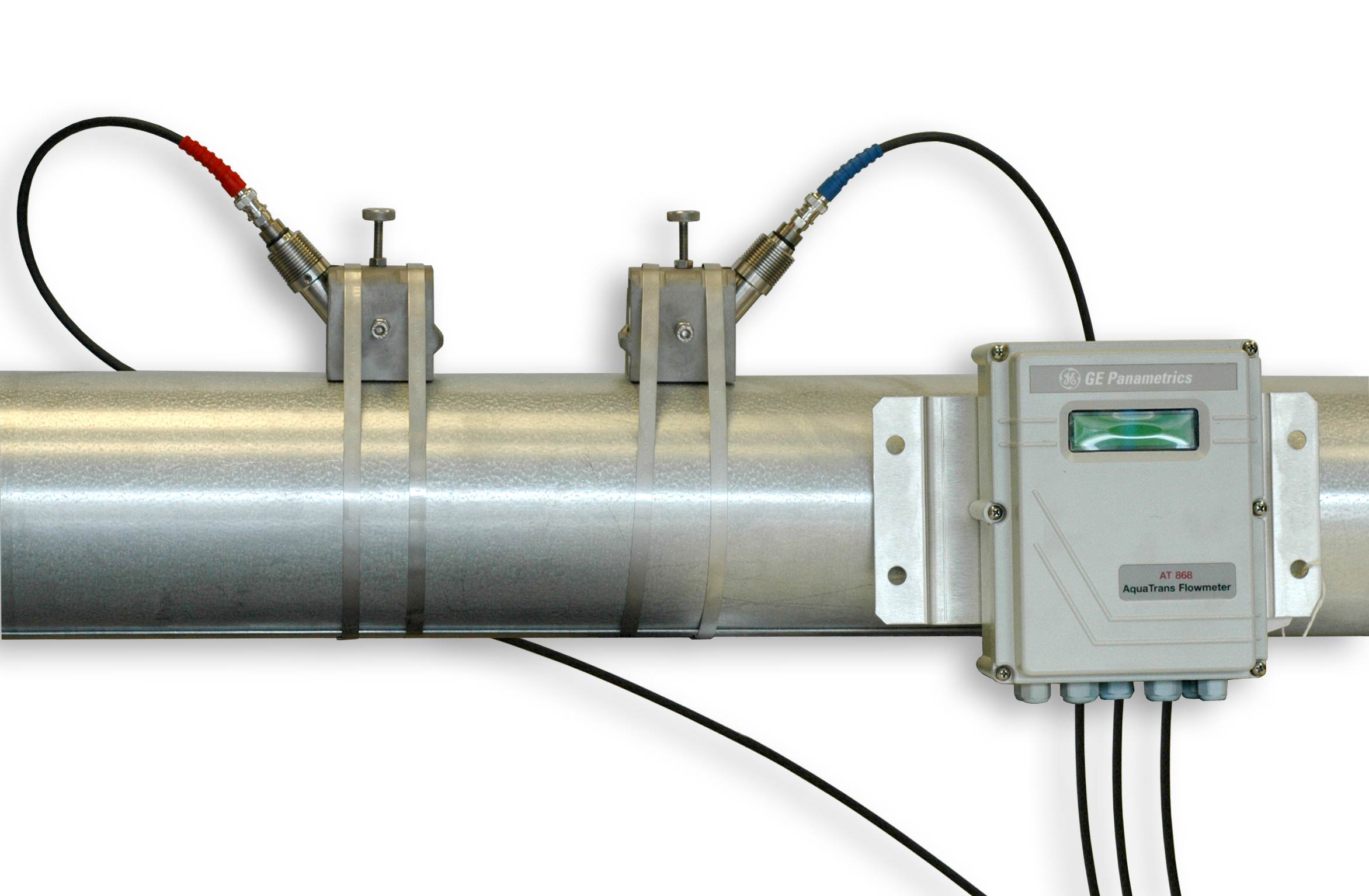

If a reliable installation technique is maintained. The VorTek U42 Commercial Series and U43 Water Series of Ultrasonic Flow Meters. Introduction The C-RL clamp-on ultrasonic flow transducers are used exclusively with the GE Measurement Control line of ultrasonic flowmeters.

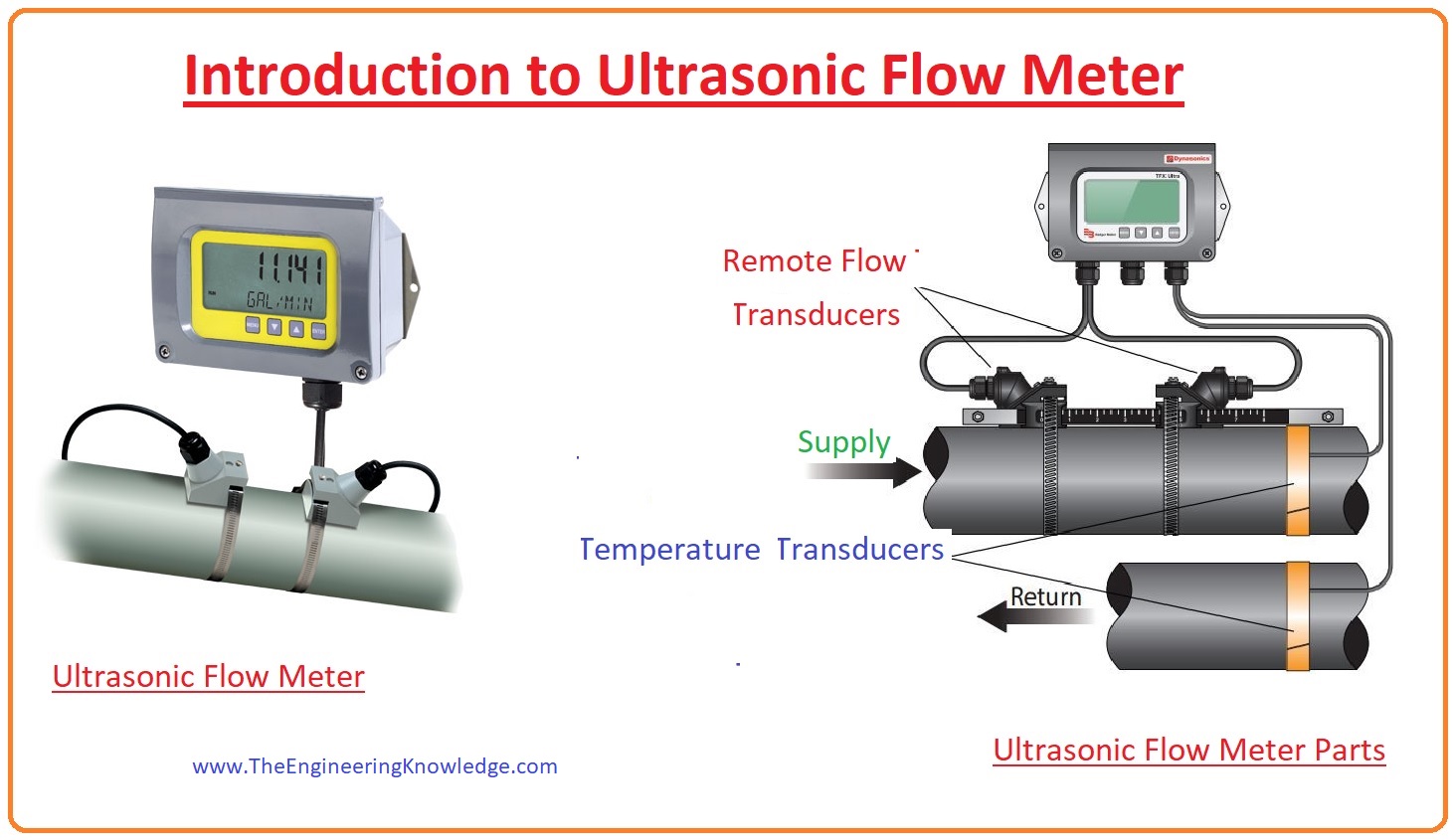

There are two types of ultrasonic flow meter technologies. INTRODUCTION ML-F8 is very unique in its structural design. The ultrasonic flowmeter can be applied to any type of standard pipe carrying clean or dirty liquids.

C-RL Installation Guide 1 1. Up to 15 cash back Clamp-on Ultrasonic Flow is a non-intrusive technology that is applied to the outside of process piping. 20 mm to 30 in.

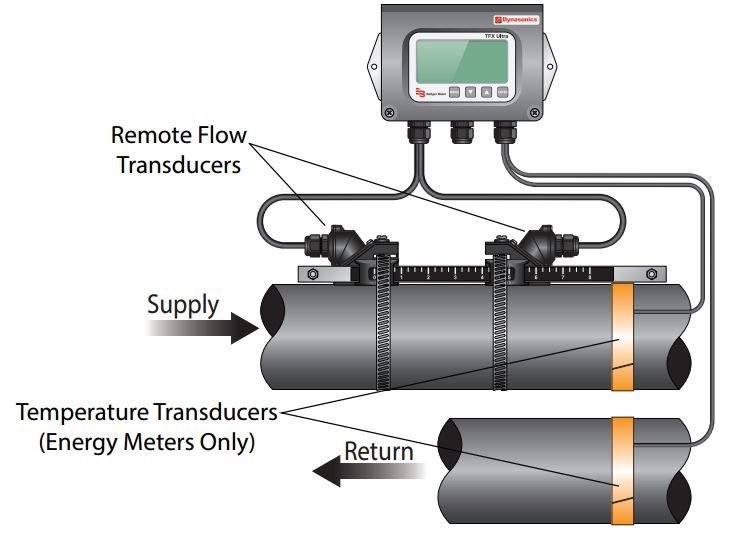

As the ultrasonic sensors are simply clamped on the pipe surface Katronic ultrasonic flow meters can be installed without the need to break into pipelines. However thanks to FLEXIMs brand new disturbance correction technology accuracy is guaranteed even under less than ideal inflow conditions reducing the necessary inlet length from 10D to a much more realistic and. 12 TYPICAL F-4300 FLOW METER INSTALLATION The F-4300 Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe.

The meter never comes in contact with the internal liquid and typically can be installed and set up within an hour. 12 TYPICAL F-4300 FLOW METER INSTALLATION The F-4300 Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe. The price depends on the type and range of flows that can be measured.

Clamp-on meters are specified to achieve two to three per cent uncertainty. They are among the most cost-effective flow measurement technologies for measuring volumetric flow rates of liquids. The sensors are fixed to the pipe using metal chains straps or mounting rails.

12 TYPICAL FP-4400 FLOW METER INSTALLATION The FP-4400 Portable Clamp-on Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe. The transducers are a non-contacting clamp-on type which will provide benefits of non-fouling operation and easy installation Transit-time flow meter utilizes two transducers that function as both ultrasonic transmitters. The spacing value shown on menu window M25 refers to the distance of inner spacing between the two.

Ideal for clean liquid applications this transit-time measurement technology reduces installation downtime and provides significant cost effectiveness when compared to inline flow measurement equipment especially in larger pipe sizes. The installation of clamp on ultrasonic flow meteris the easiest among those of all flowmeters. To obtain precise measurement under normal circumstances clamp-on flow meters demand an inlet length of at least 10D.

The meter is housed in an aluminum enclosure with silicone. Because of their simplistic design ultrasonic clamp-on meters are easy to install. Another benefit of ultrasonic clamp-on meters is that theres no.

Ultrasonic Flow Meter. Ultrasonic flow meter installation guidelines Steps to the installation of the transducers. Ultrasonic Flow Meters HOW IS THE FLOW METER INSTALLED.

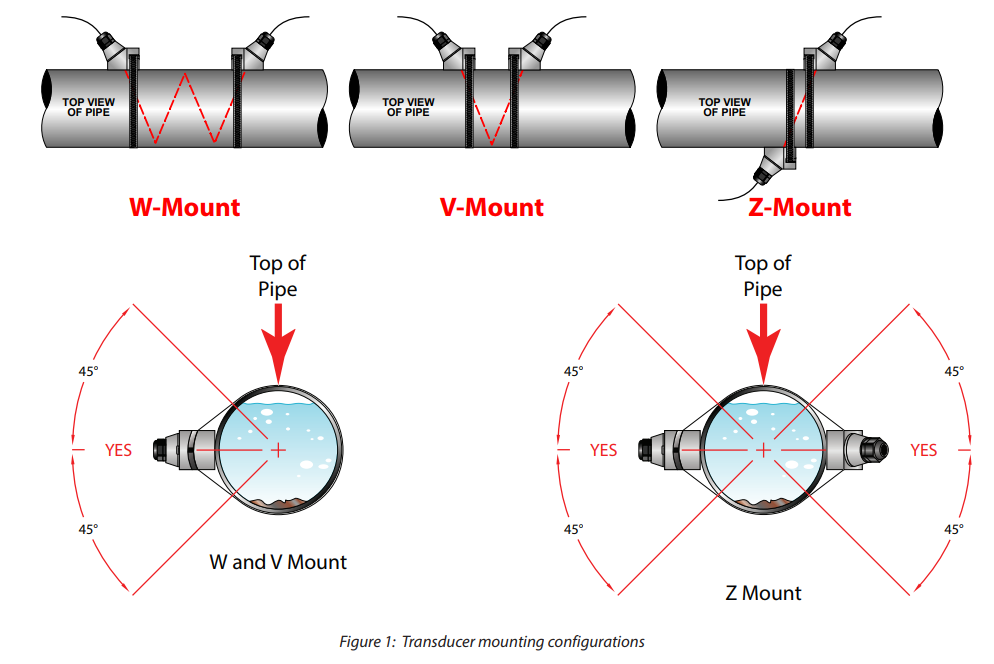

Ultrasonic flowmeters consist of clamp-on transducers that are attached on the outside wall of the pipe with flowing water Figure 1. Because of their simplistic design ultrasonic clamp-on meters are easy to install. The meter never comes in contact with the internal liquid and typically can be installed and set up within an hour.

While correct measuring point is the key point. At the time of preparation of this fact sheet the price for a single unit ranged between 2000 and 13000. The Tek-Clamp 1200A operates according to the difference in the Transit Time of Flight measured and determines the flow.

The meters clamp on to a pipes exterior without interrupting service or having to cut into or drain the pipe. Tek-Clamp 1200A Ultrasonic Clamp On Flow Meter is designed to measure the fluid velocity of liquid in a full or closed pipe. PN 47 F-4000 Series Clamp-on Ultrasonic Flow.

The meters clamp on to a pipes exterior without interrupting service or having to cut into or drain the pipe. It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications. Another benefit of ultrasonic clamp-on meters is that theres no.

Clamp- on transit-time ultrasonic flowmeters can provide bi-directional flow measurement and allow for installation without interrupting production or cutting into process piping. VorTek clamp-on ultrasonic flow meters are clamped on to the outside of the pipe and never directly contact the media inside the pipe. Turbine flow meter installation guidelines manual.

Select the installation point input the parameters get the sensor installation distance apply the couplant and bind the sensor. BSP series Clamp on ultrasonic flow meter is designed to measure the fluid velocity of liquid within a closed conduit. These transducers are used to meas ure the flow of various gases through pipes having diameters from 34 in.

Clamp on ultrasonic flow meter. TEK-CLAMP 1200A SERIES ULTRASONIC CLAMP ON FLOW METER. It is a measurement system which is both easy to install and use.

3000S is composed of a host and an external clamp sensor. Lab testing has demonstrated most installations perfonn at an accuracy level range of 1. This non-contact solution also eliminates pressure loss and potential meter fouling.

Portable Clamp On Ultrasonic Flow Meter Rental Panametrics Pt878

![]()

F 4300 Clamp On Ultrasonic Flow Meter Thermal Energy Measurement System Onicon Flow And Energy Measurement

![]()

Gray Water Surface Water Onicon Flow And Energy Measurement

Portable Ultrasonic Flow Meter Installation Tutorial How To Solve No Signal Message Youtube

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Clamp On Ultrasonic Flow Meters Installation Guidelines Rms Engineering

Ultrasonic Flow Meter Optisonic 6300 P Krohne Messtechnik For Liquids In Line Clamp On

Panametrics At868 Ultrasonic Clamp On Water Flow Meter

Clamp On Ultrasonic Gas Flow Meters

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

U1000mkii Fm Fixed Clamp On Ultrasonic Flow Meter Micronics

Clamp On Ultrasonic Flow For Liquids

Clamp On Ultrasonic Flow Meters Installation Guidelines Rms Engineering

Si 3403 Clamp On Ultrasonic Flow Meter Sino Inst

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument